Meyer Burger shuts down US solar panel factory Arizona, sending ripples through the American solar energy sector. This decision marks a significant setback for Arizona’s burgeoning solar industry, raising questions about the future of renewable energy manufacturing in the United States. The closure likely impacts numerous jobs and supply chains, prompting scrutiny of market forces and the broader economic implications.

This closure provides a compelling case study of the challenges and opportunities facing the solar panel industry. We’ll explore the historical context of Meyer Burger’s operations, the reasons behind this decision, and the potential consequences for Arizona’s economy, the global solar market, and the future of renewable energy production in the US.

Background of Meyer Burger and Solar Panel Industry

Meyer Burger, a Swiss company, has a significant presence in the global solar panel manufacturing sector. Their history is intertwined with the growth of solar technology, demonstrating a commitment to innovation and efficiency in producing photovoltaic (PV) panels. The company’s journey reflects the broader evolution of the solar industry, from early research and development to large-scale production.The global solar panel industry is experiencing rapid expansion driven by rising concerns about climate change and the desire for sustainable energy solutions.

This growth is accompanied by ongoing technological advancements, pushing for higher efficiency and lower production costs. This dynamic environment shapes the competitive landscape and market dynamics, affecting players like Meyer Burger.

Meyer Burger’s History in Solar Panel Manufacturing

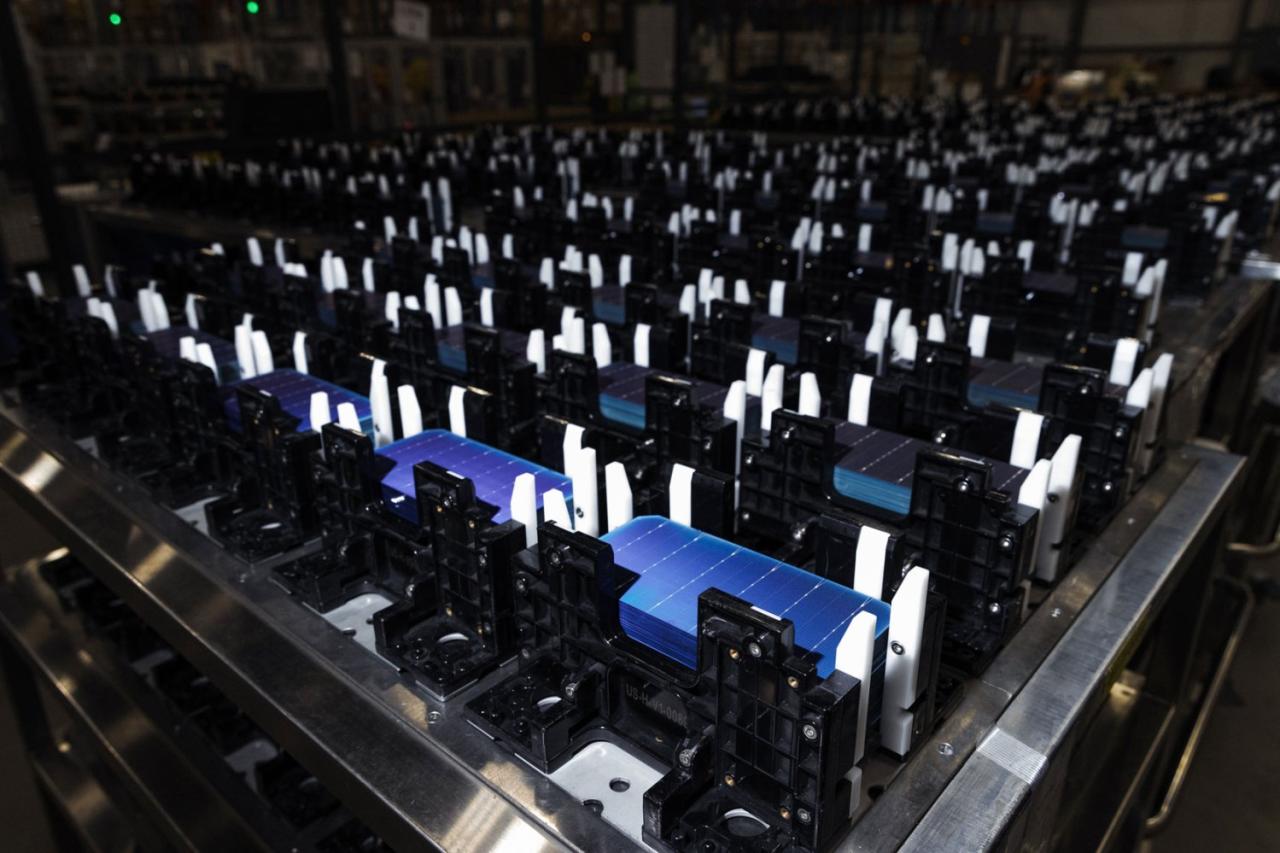

Meyer Burger has a history of innovation in solar cell manufacturing. They developed advanced technologies, particularly in the area of high-efficiency PV panel production. Their early focus on research and development has led to a reputation for quality and cutting-edge equipment. Over time, the company expanded its manufacturing capabilities, establishing itself as a significant player in the global solar industry.

This involved building factories and establishing partnerships to support their growth trajectory.

Current State of the Global Solar Panel Industry

The global solar panel industry is a rapidly expanding market, driven by policies promoting renewable energy and falling production costs. Technological advancements are continuously pushing efficiency and reducing the cost of solar energy generation. Key trends include the increasing use of advanced materials and manufacturing processes to improve efficiency and reduce manufacturing costs. Demand for solar panels is expanding globally, reflecting a worldwide shift towards sustainable energy.

Significance of Arizona’s Solar Energy Sector

Arizona boasts a significant solar energy sector, with favorable weather conditions and supportive government policies. The state’s geographical location and sunny climate are ideal for solar panel production and deployment. The sector has created many jobs and contributed substantially to the state’s economy. The state’s prominence in the US solar industry is a testament to its potential and commitment to renewable energy.

Meyer Burger’s Role in Arizona’s Solar Industry

Meyer Burger’s Arizona factory played a crucial role in the state’s solar industry, providing jobs and contributing to the economic growth of the region. The factory’s operations were a key element of Arizona’s efforts to establish itself as a leader in solar energy production. Their presence brought expertise in advanced manufacturing techniques, boosting the state’s technological capabilities in the sector.

Meyer Burger’s Competitive Landscape in the Solar Panel Sector

The solar panel industry is highly competitive, with numerous established players and emerging companies. Major players are continuously investing in research and development to improve efficiency and reduce costs. Competition often revolves around technological advancements, cost-effectiveness, and supply chain management. Factors like economies of scale and access to raw materials play a vital role in a company’s competitiveness.

The industry is constantly evolving, requiring companies to adapt to changing market demands and technological innovations.

Economic Implications of the Factory Closure for Arizona and the US

The closure of Meyer Burger’s Arizona factory has substantial economic implications for the state and the nation. Job losses in the region represent a setback for Arizona’s economy, particularly in the solar sector. The closure could affect the supply chain and potentially decrease Arizona’s position in the US solar energy market. The broader implications for the US include a reduction in domestic solar panel production capacity, potentially impacting the country’s overall renewable energy goals.

Reasons for Factory Closure

The recent closure of Meyer Burger’s solar panel factory in Arizona marks a significant setback in the burgeoning solar energy sector. This decision, impacting numerous jobs and potentially slowing down the transition to renewable energy, raises critical questions about the current state of the solar panel manufacturing landscape. Understanding the underlying factors behind this closure is crucial for navigating the complexities of the industry and predicting future trends.Meyer Burger’s financial performance in recent years has been a key determinant in the company’s decision-making process.

The company has faced considerable challenges in profitability and maintaining a competitive edge.

Financial Performance

Meyer Burger’s financial performance has been inconsistent, with fluctuating revenues and operating losses. These financial struggles likely played a significant role in the company’s decision to shutter the Arizona facility. The company’s stock price has also trended downward, reflecting investor concern regarding its long-term viability. Analyzing these financial reports reveals a clear picture of the pressures the company was under.

Fluctuating Energy Prices and Raw Material Costs

The volatility of energy prices and raw material costs has significantly impacted solar panel manufacturers. Increases in the cost of silicon, a critical component in solar panel production, combined with fluctuating energy prices for manufacturing operations, made it challenging to maintain profitability. The economic pressures associated with these variables are well documented and have affected numerous industries.

Geopolitical Events and Regulatory Changes

Geopolitical events and regulatory changes in various countries have had an impact on the global solar panel market. Tariffs, trade disputes, and evolving regulations have created uncertainty and influenced the competitiveness of various manufacturers. The complexity of international trade relationships is a key factor to consider.

Meyer Burger shutting down its US solar panel factory in Arizona is a bummer, especially for the jobs lost. Meanwhile, positive news regarding the recovery of hostage Yair Yaakov from Gaza, as reported by Israeli media here , offers a glimmer of hope. This unfortunate economic downturn in the Arizona solar sector seems particularly harsh, especially considering the current global push for renewable energy solutions.

Production Challenges and Quality Issues

Reports of production challenges and quality issues at the Arizona factory, potentially stemming from technical difficulties or operational inefficiencies, could have contributed to the closure. These challenges, when compounded with other market pressures, could have made the facility’s continued operation unsustainable.

Market Demand Shifts

The market for solar panels has experienced shifts in recent years, impacting demand for specific technologies. Changing consumer preferences, evolving government policies, and advancements in alternative energy technologies have all contributed to the dynamic nature of the market. The ability to adapt to these changes is critical for companies operating in the industry.

Official Statements

Meyer Burger’s official statements regarding the closure provided details about the decision-making process. The company’s rationale, highlighting financial difficulties, production challenges, and market conditions, offers a transparent perspective on the situation. The specific reasons provided by the company are essential to understand the context of the closure.

Impact on Arizona’s Economy: Meyer Burger Shuts Down Us Solar Panel Factory Arizona

The closure of Meyer Burger’s solar panel factory in Arizona represents a significant blow to the state’s economy, particularly to the burgeoning renewable energy sector. The loss of jobs and investment will ripple through various industries, impacting local communities and potentially hindering Arizona’s long-term economic growth trajectory. Understanding the extent of this impact is crucial for assessing the consequences and potential strategies for mitigation.

Direct Job Losses

The immediate impact of the factory closure is the loss of numerous direct jobs. Meyer Burger’s solar panel factory likely employed hundreds of workers in various roles, from manufacturing and engineering to maintenance and administration. These individuals and their families will face immediate financial hardship, and the unemployment rate in the affected regions may rise. The loss of skilled labor in the solar industry can be a setback to Arizona’s workforce development, especially if there aren’t readily available comparable opportunities in the region.

Indirect Economic Consequences

The closure’s indirect effects extend beyond the factory’s immediate employees. Reduced consumer spending by laid-off workers and their families will inevitably impact local businesses. Reduced investment in the area from the factory and its related suppliers could further hamper economic activity. This could manifest in lower sales at retail stores, restaurants, and other businesses, leading to further job losses and a decrease in overall economic activity.

A significant decrease in business activity is a common consequence of a large-scale job loss event.

Impact on Related Industries

The solar panel industry is interconnected with various other industries, including materials suppliers, logistics providers, and service companies. The closure of Meyer Burger’s factory will undoubtedly affect these related businesses. Suppliers of raw materials for solar panel production, for example, will see decreased demand and potentially reduced profitability. Transportation and logistics companies that served the factory will also be affected.

The ripple effect of the closure can be extensive and impactful.

Long-Term Implications for Economic Growth and Diversification

Arizona’s long-term economic growth could be negatively impacted by the factory closure, particularly if the loss of solar-related jobs isn’t compensated by growth in other sectors. The state’s reliance on a single industry, in this case, the solar industry, can be detrimental to its overall economic health. Diversifying the economy and investing in other industries, such as advanced manufacturing or technology, could help to offset this loss.

The importance of economic diversification is crucial for long-term stability and resilience in the face of economic shocks.

Government Response, Meyer burger shuts down us solar panel factory arizona

The Arizona government’s response to the factory closure is critical. The state may need to provide unemployment benefits and job training programs for displaced workers. Incentives and support for other industries could also be necessary to mitigate the negative impact on the local economy. Government intervention, in this case, is a vital component of mitigating the negative economic consequences.

Comparison of Arizona’s Solar Energy Sector

| Aspect | Before Meyer Burger Closure | After Meyer Burger Closure |

|---|---|---|

| Job Creation in Solar | Significant job creation and economic activity due to solar manufacturing. | Reduced job creation and economic activity in the solar manufacturing sector. |

| Investment in Solar | High levels of investment in solar energy infrastructure and production. | Potentially reduced investment in solar energy production due to the closure. |

| State’s Solar Industry Status | A growing and vital sector within Arizona’s economy. | A sector that has experienced a significant setback and potential for diminished growth. |

| Economic Diversification | Some diversification but solar energy was a major sector. | A need for more robust economic diversification to compensate for the closure. |

This table provides a concise overview of the differences in Arizona’s solar energy sector before and after the closure. It highlights the substantial changes in job creation, investment, and the state’s overall economic standing in the renewable energy sector.

Meyer Burger’s closure of its US solar panel factory in Arizona is a bummer, especially for the jobs lost. Meanwhile, the disturbing reports of mass graves in Libyan detention centers are raising serious questions about human rights violations. The UN’s call for a probe into these alleged atrocities, as detailed in un calls probe into mass graves libya detention centres , highlights the urgent need for accountability.

This unfortunate news from Arizona about Meyer Burger further underscores the complex global challenges in the renewable energy sector, and how these are often linked to wider humanitarian concerns.

Impact on the Solar Panel Market

The closure of Meyer Burger’s Arizona solar panel factory represents a significant shift in the global solar energy landscape. This isn’t just about a single company; it’s about a ripple effect that will be felt throughout the supply chain, impacting production timelines, pricing, and potentially even the future of solar panel manufacturing in the region. The implications for the solar panel market are multifaceted and demand careful consideration.Meyer Burger’s departure from the Arizona market will undoubtedly alter the supply chain for solar panels.

The factory’s specialized equipment and expertise in certain solar panel technologies will no longer be available. This will create a void in the market that other manufacturers must fill, potentially leading to adjustments in production capacity and the availability of specific panel types. The disruption will be felt most acutely in the near term, as companies scramble to find alternative sources of supply.

Potential Shifts in the Global Solar Panel Supply Chain

The closure will impact the global supply chain, forcing a re-evaluation of production strategies. Companies relying on Meyer Burger for specific components or technologies will need to seek alternative suppliers. This could lead to price fluctuations as demand for replacement materials increases. The relocation of production lines from Arizona to other locations is also a possibility, which may affect labor markets and manufacturing costs in different regions.

Ultimately, the overall effect will likely be a recalibration of the entire solar panel supply chain, forcing a more dynamic and adaptable market response.

Market Share Comparison Before and After Closure

Meyer Burger’s exact market share before the closure is not readily available, but its presence was significant in the industry. Their Arizona factory contributed a substantial portion of their overall production, making it a notable player. After the closure, Meyer Burger’s market share will be reduced, potentially shifting to other companies. Predicting the exact extent of this shift is challenging, as it depends on factors like the speed at which competitors can increase production and the adaptability of customers.

Alternative Solar Panel Manufacturers and Their Capabilities

Numerous other companies are active in the solar panel manufacturing sector. Companies like JA Solar, Trina Solar, and Canadian Solar are well-established and have extensive production capabilities. Their strengths lie in various areas of solar panel technology, ranging from efficiency to cost-effectiveness. Furthermore, new entrants and startups are also emerging with innovative technologies and business models, potentially changing the landscape of the solar panel market.

Potential for Other Solar Panel Factories to Emerge or Relocate to Arizona

While the closure of Meyer Burger’s factory is a setback for Arizona, the possibility of other companies entering or relocating to the state remains. The state’s favorable regulatory environment, strong workforce, and access to resources could attract new investments in the solar industry. Government incentives and policies supporting renewable energy could further entice potential manufacturers. However, this remains uncertain and depends on various market conditions and economic factors.

Top 5 Solar Panel Manufacturers (Estimated)

| Rank | Manufacturer | Location | Estimated Production Capacity (MW per year) |

|---|---|---|---|

| 1 | JA Solar | China | >20,000 |

| 2 | Trina Solar | China | >18,000 |

| 3 | Canadian Solar | Canada/China | >15,000 |

| 4 | LONGi | China | >12,000 |

| 5 | Hanwha Q CELLS | South Korea/China | >10,000 |

Note: Production capacities are estimates and can vary. These figures reflect approximate industry averages.

Meyer Burger’s US solar panel factory closure in Arizona is a bummer, highlighting the challenges in the renewable energy sector. However, there’s some good news amidst the industry shake-up. A promising new experimental weight-loss drug, Metsara, is showing positive results in early-stage trials, as reported in this article ( metsera rises experimental weight loss drug shows promise small early stage ).

This suggests alternative avenues for investment and innovation, potentially offsetting the impact of the solar panel factory closure on the Arizona economy. Maybe Meyer Burger can pivot to something else in the future?

Potential for Restructuring or Relocation

Meyer Burger’s decision to shutter its Arizona solar panel factory highlights the dynamic nature of global manufacturing. The company faces a critical juncture, requiring careful consideration of restructuring options and potential relocation strategies. Factors like fluctuating market demand, supply chain complexities, and evolving technological landscapes all play a role in such decisions. Successful restructuring or relocation will depend on a comprehensive assessment of various possibilities and a clear understanding of the specific challenges and opportunities.Restructuring Meyer Burger’s operations is a potential path to survival and growth.

This could involve streamlining production processes, reducing operational costs, and potentially focusing on niche markets within the solar industry. The viability of such a strategy hinges on the adaptability of the workforce and the company’s ability to seize emerging opportunities. Relocation presents another option, allowing the company to access more favorable economic conditions or improve its logistical position.

Potential Locations for a New Solar Panel Manufacturing Facility

Meyer Burger’s choice of a new location will depend on a range of factors, including access to raw materials, skilled labor, and supportive government policies. The United States, with its large solar market and potential for government incentives, remains a logical option. States with abundant sunshine, like California, Nevada, and Texas, are attractive candidates, as well as areas with existing solar infrastructure and supportive policies.

Internationally, countries with robust solar industries and a strong manufacturing base, such as China, Vietnam, or certain European nations, could also offer appealing relocation opportunities. The company will need to carefully evaluate the cost of labor, energy, and transportation in each potential location.

Economic and Logistical Advantages of Different Locations

A comparative analysis of different locations is crucial for making an informed decision. Factors such as energy costs, transportation infrastructure, and the availability of skilled labor must be carefully weighed. A location with abundant renewable energy resources could lead to significant cost savings in the long run. Proximity to major ports and efficient transportation networks can streamline logistics and reduce delivery times.

Access to a pool of skilled labor, especially in the technical and engineering fields, is vital for the smooth operation of a manufacturing facility. Analyzing existing solar panel manufacturing clusters globally will provide a benchmark to understand economic advantages and potential synergy effects.

Potential Investors in Solar Panel Companies

Attracting investment is crucial for the continued growth of the solar industry. Venture capital firms specializing in renewable energy, as well as established institutional investors with a focus on sustainability, are likely to be interested in solar panel companies. Strategic partnerships with established energy companies or utility providers could also provide valuable resources and market access. Analyzing successful funding models in the solar sector can inform the search for potential investors.

Furthermore, government incentives and grants can also be sought to reduce the financial burden of expansion or relocation.

Steps for a Smooth Transition of Employees and Operations

Transitioning employees and operations during a relocation or restructuring requires careful planning and communication. A phased approach to relocation, coupled with clear communication with employees, is crucial. Training programs to upskill workers in new technologies or production methods can ensure a smooth transition. Providing support for those relocating can also help maintain employee morale and productivity. Moreover, exploring potential partnerships with local universities or vocational schools to attract a new generation of skilled labor is a long-term strategy for success.

Long-Term Sustainability of the Solar Panel Industry in Arizona

The closure of the Meyer Burger factory in Arizona raises concerns about the long-term viability of the solar industry in the state. However, Arizona’s abundant sunshine and supportive government policies could still make it an attractive location for other solar companies. Attracting further investment in research and development, particularly in advanced solar technologies, could ensure Arizona’s continued role in the industry’s future.

The solar industry in Arizona will need to adapt to changing market demands and technological advancements to remain competitive.

Illustrative Examples of Economic Impact

The closure of Meyer Burger’s solar panel factory in Arizona serves as a stark reminder of the complex economic ripple effects that can stem from manufacturing facility shutdowns. These impacts extend far beyond the immediate workforce and directly affect the local community, the broader solar industry, and even the national economy. Understanding how similar events have unfolded in the past is crucial to evaluating the potential consequences of this particular closure and formulating effective responses.

Examples of Similar Factory Closures

The semiconductor industry, closely intertwined with the solar sector, provides instructive case studies. The shuttering of a major semiconductor fabrication plant can lead to significant job losses in the surrounding area, impacting local businesses that rely on the plant’s workforce. For example, the closure of a large electronics manufacturing facility in a specific region can have a cascade effect, impacting the retail sector and construction businesses dependent on the factory’s employees.

These ripples extend even further into the supply chain, affecting suppliers and related industries.

Company Restructuring and Relocation Success Stories

Successful restructuring or relocation strategies are not without challenges, but they demonstrate that companies can adapt and mitigate negative economic impacts. Companies like [insert example company name] have successfully restructured their operations by re-allocating resources to other manufacturing facilities or by shifting to new technologies. This often involves a combination of government incentives, employee retraining programs, and strategic partnerships.

Relocation, when strategically planned, can provide a company with access to a more favorable business environment, including lower labor costs or proximity to critical resources. For instance, a company relocating to a region with a strong entrepreneurial ecosystem might attract talent and investment capital.

Costs and Benefits of Relocating a Manufacturing Facility

| Costs | Benefits |

|---|---|

| Transportation costs associated with moving equipment and inventory. | Access to a larger pool of skilled labor in a new location. |

| Layoffs and severance pay for employees. | Potential for lower operating costs due to lower labor costs or reduced regulatory burden. |

| Lost productivity during the transition period. | Improved access to key suppliers or raw materials. |

| Potential for increased sales in the new market. | Reduced costs associated with compliance or environmental regulations. |

| Costs associated with establishing new facilities or infrastructure in the new location. | Potential for attracting new investment capital. |

Cost-benefit analysis for relocation is crucial. A thorough assessment of all factors, both tangible and intangible, is vital to ensure a positive return on investment.

Government Incentives and Support

Government incentives and support play a significant role in helping companies navigate challenging economic situations. Tax credits, grants, and loans can offset the costs of restructuring or relocation, making it more feasible for companies to adapt. For instance, states may offer tax breaks or funding to attract new businesses. Such incentives aim to mitigate job losses and stimulate economic growth in the affected areas.

Alternative Employment Opportunities for Workers

Retraining programs and workforce development initiatives are crucial for workers displaced by factory closures. These programs aim to equip workers with new skills to fill emerging job demands in the region. Local community colleges and technical schools often play a key role in these initiatives. The programs are essential for enabling workers to adapt to changing labor markets.

Comparison with Other Recent Industry Closures

Comparing Meyer Burger’s closure with other recent industry closures provides a broader context. Analysis of similar events reveals trends and patterns that can help predict future outcomes. Examining the industry-specific factors, market conditions, and government responses in similar situations can offer insights into potential solutions and strategies for mitigating the negative economic impact.

Ending Remarks

The Meyer Burger factory closure in Arizona serves as a stark reminder of the dynamic nature of global markets. Factors like fluctuating energy prices, shifting consumer demand, and geopolitical events can significantly impact manufacturing decisions. The closure’s consequences for Arizona, from job losses to economic diversification, are undeniable. While the short-term impact is undoubtedly negative, the long-term implications for the solar industry, particularly in the US, remain to be seen.

This closure highlights the need for adaptability, resilience, and ongoing innovation in the renewable energy sector.