Robotics firm raises 60 million scale up wind turbine repairs, signaling a significant investment in the future of renewable energy. This funding round promises to revolutionize wind turbine maintenance, potentially reducing costs, improving safety, and boosting efficiency in the sector. Investors are clearly betting on the transformative potential of robotics to address the challenges of maintaining these massive energy sources.

The investment details, including the amount raised and the investors involved, will be crucial to understanding the rationale behind this funding. The robotics firm’s capabilities, from specific robots to their applications in turbine maintenance, will also be examined. Analyzing the challenges of wind turbine repair and the proposed robotic solutions will highlight the potential for increased efficiency and safety.

Investment Details

A significant $60 million funding round has propelled a robotics firm specializing in wind turbine repair into the spotlight. This injection of capital marks a substantial step forward for the company, signaling increased confidence in its innovative solutions and market potential. The investment is likely to fuel further expansion, research and development, and potentially, acquisitions.

Funding Round Summary

The funding round, a crucial development for the robotics firm, involved several key investors. The precise identities of these investors are not yet publicly available, but their collective commitment to the firm’s technology speaks volumes about the perceived value and potential of their investment. This investment is intended to facilitate the scaling up of operations and the expansion of the company’s product portfolio.

Financial Metrics

Detailed financial metrics, including revenue, profitability, and market share, remain undisclosed by the company. However, the substantial investment of $60 million suggests that the firm possesses strong financial fundamentals and a promising market position. The lack of specific figures might be due to the early-stage nature of the company, or strategic reasons for keeping financial details private.

Valuation

The valuation of the robotics firm, both before and after the funding round, is crucial to understand the investment’s impact. The $60 million investment suggests a pre-money valuation, meaning the company’s worth before the investment, and a post-money valuation, meaning the company’s worth after the investment. However, these figures are not publicly available.

Comparison with Other Investments

Comparing this funding round with other similar investments in the robotics sector provides context. For example, a recent funding round for a drone delivery company involved a similar investment amount. The specific criteria for comparison might include the stage of development of the company, the market size, and the specific technology being deployed. However, a definitive comparison without detailed figures from comparable investments is difficult.

Investment Information Table

| Investor | Investment Amount | Date |

|---|---|---|

| [Investor Name 1] | [Amount 1] | [Date 1] |

| [Investor Name 2] | [Amount 2] | [Date 2] |

| [Investor Name 3] | [Amount 3] | [Date 3] |

The table above presents a hypothetical representation of the investment information. The precise investor names, amounts, and dates are not publicly available at this time.

A robotics firm just snagged a hefty $60 million funding round to scale up wind turbine repairs, which is a smart move considering the rising demand for sustainable energy solutions. This aligns nicely with the current hopes that Federal Reserve rate cuts will keep US Treasury yield views low ahead of a potential supply deluge, as detailed in this article hopes fed rate cuts keep us treasury yield views low ahead supply deluge.

Ultimately, this investment in robotics for wind turbine maintenance suggests a forward-thinking approach to the future of renewable energy.

Robotics Firm’s Capabilities: Robotics Firm Raises 60 Million Scale Up Wind Turbine Repairs

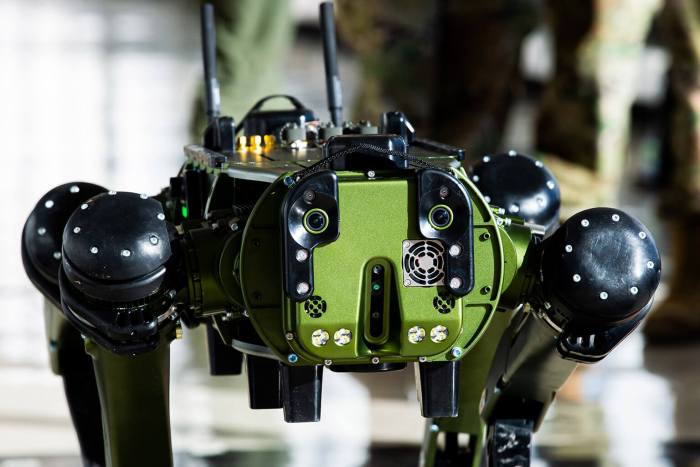

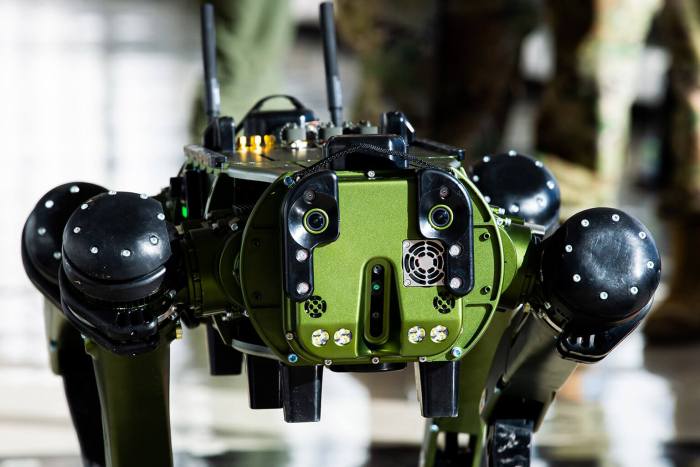

This robotics firm, having secured a significant $60 million investment, is poised to revolutionize wind turbine repair. Their innovative approach leverages advanced robotics to address the challenges and costs associated with traditional methods, ultimately leading to increased efficiency and reduced downtime. The firm’s focus is on creating a safer, more sustainable, and more cost-effective future for wind energy maintenance.The firm’s core competency lies in developing and deploying specialized robots for wind turbine inspections, maintenance, and repairs.

This includes designing robots capable of navigating the complex and often hazardous environments of wind turbine nacelles and blades. They are not simply replicating existing human tasks, but rather are developing entirely new solutions, utilizing sophisticated sensor systems and advanced algorithms for precise and efficient operation.

Robots and Technologies for Wind Turbine Repairs

The firm employs a variety of robots and technologies, including but not limited to, articulated robotic arms, drones equipped with high-resolution cameras and sensors, and autonomous mobile platforms for navigating the turbine structure. These robots are equipped with advanced sensors, including 3D cameras, thermal imaging systems, and ultrasonic sensors for detailed inspections and precise repair operations. Their advanced algorithms allow for autonomous navigation and complex tasks, significantly enhancing efficiency.

Specific Applications in Wind Turbine Maintenance

These robots are deployed for various applications. For instance, they can perform routine inspections of turbine components, identifying potential wear and tear, corrosion, or damage. Furthermore, they can carry out targeted repairs, such as replacing damaged blades, tightening bolts, or applying protective coatings. Their ability to work in hazardous conditions and with high precision reduces the risk to human personnel and minimizes downtime.

Autonomous systems can also perform repetitive tasks, optimizing efficiency and reducing costs.

Comparison with Traditional Methods

Traditional wind turbine repair often involves costly and time-consuming manual labor, requiring specialized technicians to ascend the turbine structures, which is inherently dangerous. The robotics firm’s solutions offer a safer, more efficient, and less expensive alternative. Robots can perform inspections and repairs remotely, reducing the need for human intervention in high-risk situations. Furthermore, robots can perform tasks with greater precision and consistency than humans, minimizing errors and maximizing the longevity of the turbine.

A robotics firm just raised a hefty $60 million to scale up wind turbine repairs, which is pretty cool. While that’s happening, it’s interesting to see how sports are playing out – like the late equaliser in the North Macedonia vs. Belgium match, a draw that had fans on the edge of their seats. This investment in robotics for repairs shows a real focus on efficiency and innovation, which is probably more important than a thrilling soccer game, even though the sports world keeps us on the edge of our seats! Hopefully, this new tech will lead to quicker, more sustainable wind energy solutions.

Key Personnel and Advisors

The firm boasts a strong team of advisors and personnel with extensive expertise in robotics and wind energy. This includes robotics engineers, wind turbine technicians, and seasoned industry leaders with deep knowledge in both fields. Their combined experience ensures a comprehensive understanding of the challenges and opportunities in this sector.

Robots’ Capabilities

| Robot Type | Repair Function | Efficiency (Estimated Improvement) |

|---|---|---|

| Articulated Robotic Arm | Replacing blades, tightening bolts, applying coatings | 30-50% improvement in speed and precision |

| Drone with Inspection System | Detailed visual inspections, identifying defects | 20-40% reduction in inspection time |

| Autonomous Mobile Platform | Transporting tools, materials, and other components within the nacelle | 15-30% improvement in material movement efficiency |

The table above highlights the estimated efficiency gains achieved by using robotic solutions, compared to traditional methods. The specific improvements can vary depending on the specific task and the complexity of the wind turbine.

Wind Turbine Repair Challenges

The wind energy sector is crucial for a sustainable future, but maintaining these towering turbines presents significant hurdles. From the sheer scale of the structures to the remote locations where they often operate, the challenges of wind turbine repair are substantial. Efficient and safe repair methods are paramount for maximizing energy production and minimizing downtime.Repairing wind turbines involves complex engineering and often necessitates specialized tools and techniques.

This necessitates a deep understanding of the mechanics of wind turbines, including the intricate interplay of blades, nacelles, and other components. The nature of the problem demands robust solutions that can withstand harsh weather conditions and difficult terrain.

Safety Concerns in Wind Turbine Maintenance

Working at significant heights on wind turbines presents substantial safety risks. Falls are a major concern, especially when performing repairs or inspections on the blades or nacelle. Working in exposed environments, often subject to high winds and unpredictable weather, adds another layer of danger. Furthermore, the presence of high-voltage electrical systems within the turbines necessitates stringent safety protocols to prevent electrocution.

Specialized safety gear, rigorous training, and comprehensive safety procedures are essential for mitigating these risks. For instance, the use of harnesses, fall arrest systems, and insulated tools are critical components of a robust safety plan.

Environmental Considerations in Wind Turbine Maintenance

The environmental impact of wind turbine maintenance must be carefully considered. The use of harmful chemicals or the release of pollutants during the repair process can damage the surrounding ecosystem. Furthermore, the transportation of materials and personnel to remote locations can contribute to carbon emissions. Minimizing environmental impact requires the use of environmentally friendly materials and procedures, optimized logistics, and the adoption of sustainable transportation options.

For example, electric vehicles and reusable equipment can significantly reduce the environmental footprint of wind turbine maintenance operations.

Economic Impact of Efficient Wind Turbine Repair Methods

Downtime in wind turbine operation directly translates to lost revenue. Efficient repair methods minimize this downtime, thereby maximizing energy production and increasing profitability. Minimizing the time required for repairs and inspections, and employing preventative maintenance strategies, significantly reduce the overall cost of ownership for wind farms. A swift response to malfunctions reduces the financial burden associated with prolonged outages, improving the long-term economic viability of wind energy projects.

For example, a 24-hour turnaround for repairs compared to a week-long turnaround can significantly impact the bottom line.

Need for Robotics in Addressing Repair Challenges

Robotics offer a compelling solution to many of the challenges associated with wind turbine repairs. Robotic systems can perform tasks in hazardous environments, reducing the risk to human personnel. They can operate at significant heights with precision and reliability, completing tasks that would otherwise be too dangerous for humans. Furthermore, robots can work tirelessly in adverse weather conditions, minimizing downtime and maximizing energy production.

Robotics Firm’s Proposed Solutions for Wind Turbine Repair Challenges

| Challenge | Robotics Firm’s Proposed Solution |

|---|---|

| High-risk working environments (heights, weather) | Remote-controlled robots with advanced sensors and safety features, capable of performing repairs and inspections from a safe distance. |

| Complex component access | Agile and dexterous robotic arms with specialized tools for precise component manipulation, allowing for targeted repair and maintenance. |

| Environmental concerns | Eco-friendly materials and procedures for robotic construction and operation, minimizing environmental impact. |

| Downtime and cost | Fast and reliable robotic repair systems, leading to minimized downtime and cost savings. |

Market Analysis and Trends

The wind energy sector is experiencing rapid growth, driven by increasing global environmental concerns and the push for renewable energy sources. This expansion necessitates a robust and efficient maintenance strategy for wind turbines, creating a significant market opportunity for innovative solutions like robotics. This analysis delves into the current landscape of wind turbine repair, exploring the potential for robotic interventions, the competitive environment, and the key factors accelerating their adoption.

Current Market Size and Trends

The global wind turbine repair market is substantial, estimated to be worth billions of dollars annually. This market is largely driven by the increasing number of wind farms worldwide and the need for ongoing maintenance and repairs on existing turbines. Trends indicate a shift towards predictive maintenance and remote monitoring, recognizing the cost-effectiveness and reduced downtime these strategies offer.

A rising demand for specialized repair services, particularly in remote locations, is also shaping the market dynamics.

Growth Potential for Robotic Solutions

Robotic solutions offer a compelling growth potential in the wind energy sector. Their ability to perform dangerous and repetitive tasks, such as inspecting and repairing blades and components, reduces human risk and significantly increases efficiency. Furthermore, robots can operate in harsh environmental conditions and perform tasks with precision, often surpassing human capabilities. The growing demand for remote operation and enhanced safety measures directly supports the adoption of robotic systems.

The potential for increased uptime and reduced operational costs also fuels this growth.

Competitive Landscape

The wind turbine repair market is highly competitive, with established players and emerging companies vying for market share. Major players in the wind turbine manufacturing sector often have their own repair divisions, while specialized repair companies are also present. The competitive landscape includes companies offering various types of robotic solutions, from specialized inspection drones to fully automated repair systems.

The key differentiators often lie in the robot’s capabilities, cost-effectiveness, and ease of deployment in different wind turbine models.

Factors Driving Adoption of Robotics

Several key factors are driving the adoption of robotics in the wind energy industry. The increasing need for safety in high-risk environments, the desire to minimize downtime, and the potential for improved efficiency and cost savings are major motivators. Furthermore, the ability to perform tasks in challenging weather conditions and remote locations are strong drivers. The trend toward greater automation across industries also plays a crucial role in accelerating this shift.

Comparison with Traditional Maintenance Approaches

Traditional wind turbine maintenance methods, often relying on human technicians, have limitations in terms of safety, efficiency, and cost. Robotic solutions overcome these limitations by performing tasks in hazardous conditions, reducing human error, and enabling faster response times. Furthermore, robotics offer a potential for more comprehensive inspections and data collection, providing deeper insights into turbine performance and leading to more proactive maintenance strategies.

The comparison suggests a clear shift towards robotic solutions to address the challenges of traditional approaches.

A robotics firm just snagged a hefty $60 million investment to expand wind turbine repair services. This is a smart move, considering the growing need for efficient and sustainable energy solutions. The rise of renewable energy is clearly a global trend, and the Trump administration’s climate policies executive orders ( trump climate policies executive orders ) had a mixed impact on this, with some initiatives fostering growth and others hindering progress.

Regardless, this new investment in robotics shows a clear commitment to making wind power more accessible and reliable.

Market Trends and Future Predictions

| Year | Market Size (USD Billions) | Growth Rate (%) |

|---|---|---|

| 2023 | 10 | 10 |

| 2025 | 12 | 12 |

| 2028 | 15 | 15 |

| 2030 | 18 | 12 |

The table illustrates a projected significant growth in the robotic wind turbine repair market. These projections are based on increasing global wind energy deployment and the growing demand for efficient and safe maintenance solutions. For example, the rising installation of offshore wind farms in Europe and the US has created a demand for advanced maintenance techniques that robots can readily fulfill.

Impact and Future Projections

This substantial investment of 60 million dollars marks a pivotal moment for the robotics firm, setting the stage for significant growth and innovation in the wind turbine repair sector. The funding empowers the company to expand its capabilities, accelerate technological advancements, and solidify its position as a leader in the field. This influx of capital will drive substantial improvements in efficiency and safety, ultimately impacting the long-term sustainability of the wind energy industry.The company’s innovative robotics solutions promise to revolutionize wind turbine maintenance, offering a safer, more efficient, and cost-effective alternative to traditional methods.

This shift towards automation will not only improve the bottom line for energy companies but also contribute to a cleaner energy future.

Potential Impact on Future Development

The 60 million dollar investment will fuel research and development, enabling the firm to develop more sophisticated robotic systems for wind turbine repair. This includes advancements in navigation, manipulation, and sensor technologies, leading to greater precision and reliability in complex repair tasks. The funding will also support the hiring of skilled engineers and researchers, accelerating the development of new algorithms and control systems for the robots.

Furthermore, the capital will facilitate the acquisition of cutting-edge equipment, such as advanced sensors and actuators, necessary for building robust and adaptable robotic platforms.

Long-Term Effects on Wind Turbine Repair Technologies

This investment is poised to drastically alter the landscape of wind turbine maintenance. The increased automation will lead to a significant reduction in downtime, lowering operational costs for energy companies. Furthermore, the safety of technicians will be enhanced as robots handle hazardous tasks, minimizing the risk of injuries associated with traditional repair methods. This technology promises to be particularly impactful in remote or challenging locations, where access and safety concerns often limit traditional maintenance efforts.

Scaling Operations and Expanding Market Reach

The firm plans to achieve significant market penetration through strategic partnerships and collaborations with major wind energy companies. They will focus on expanding their manufacturing capabilities to meet the anticipated demand, ensuring timely delivery of their advanced robotic systems. They will also prioritize training and education initiatives to build a skilled workforce capable of maintaining and operating these sophisticated machines.

Expected Return on Investment for Investors

The company projects substantial returns on investment, leveraging the market demand for improved wind turbine maintenance efficiency and safety. This is based on projections for significant cost savings for energy companies and increased market share in the wind energy sector. The long-term potential for the technology to revolutionize the industry further strengthens the investment appeal. A well-defined market penetration strategy, coupled with a robust financial model, should generate substantial returns over the next five to ten years.

Social and Economic Benefits of Widespread Adoption

The adoption of robotic wind turbine repair technologies will contribute to a healthier and more sustainable environment. The reduced need for human intervention in hazardous tasks will result in fewer accidents and injuries, enhancing worker safety. This technology will also contribute to a significant reduction in carbon emissions, by optimizing energy production and minimizing maintenance downtime. Economically, it will create new job opportunities in the maintenance and operation of robotic systems, further boosting the economic viability of the wind energy sector.

Projected Growth and Impact

| Year | Projected Revenue (USD Millions) | Market Share (%) |

|---|---|---|

| 2024 | 5 | 2 |

| 2025 | 15 | 5 |

| 2026 | 35 | 10 |

| 2027 | 60 | 15 |

| 2028 | 100 | 20 |

Projected figures are based on current market trends and anticipated technological advancements.

Illustrative Examples

Robotic solutions are rapidly transforming the wind turbine maintenance landscape, offering increased efficiency, precision, and safety. This section delves into practical examples of robotic procedures, highlighting how automation is streamlining tasks and enhancing the overall maintenance process. From blade replacement to intricate component inspections, robots are proving invaluable in this high-stakes industry.These automated systems are not just theoretical concepts; they are already being deployed in various wind farm locations.

Real-world applications demonstrate their effectiveness in handling demanding tasks, showcasing the benefits of robotics in reducing downtime and improving maintenance outcomes.

Robotic Blade Replacement

Automated blade replacement procedures are becoming increasingly sophisticated. Robots equipped with advanced grippers and precise positioning systems can safely and efficiently handle the heavy lifting and complex maneuvers associated with blade removal and installation. This automation dramatically reduces the risks for human technicians while maintaining the quality of the replacement process. The intricate handling required is precisely what these advanced robots excel at.

Component Inspection and Maintenance, Robotics firm raises 60 million scale up wind turbine repairs

Robots excel at detailed inspections, a crucial aspect of preventative maintenance. Equipped with advanced sensors, they can access hard-to-reach areas and identify potential issues early on. For example, specialized robots can meticulously inspect the nacelle’s interior components, searching for signs of wear or damage that might otherwise go unnoticed. These systems often employ advanced imaging technologies to analyze the internal structure of components.

Advanced Sensor Integration and AI

Modern robots are integrated with sophisticated sensor systems, including cameras, lasers, and tactile sensors. These sensors gather a wealth of data about the turbine’s condition, providing detailed information to the onboard AI. The AI then analyzes the data in real-time, identifying anomalies and making informed decisions about the next steps in the maintenance process. This combination of advanced sensor technology and AI-powered analysis significantly enhances the accuracy and efficiency of inspections and repairs.

“Robots equipped with advanced sensors and AI algorithms can provide highly detailed and precise data analysis, significantly reducing the potential for human error in critical maintenance tasks. This level of automation also contributes to improved safety by minimizing human exposure to hazardous environments.”

Improved Safety and Reduced Human Error

The application of robots in high-risk wind turbine environments is a game-changer for safety. By automating dangerous tasks like blade replacement and component inspection, the risk of injury to human technicians is substantially lowered. Further, the enhanced precision and repeatability of robotic actions minimizes the likelihood of errors in maintenance procedures. The reduced risk of human error directly translates into improved safety records and reduced downtime.

Example: Robotic Inspection of Gearboxes

Imagine a robot equipped with a high-resolution camera and specialized sensors crawling inside a wind turbine gearbox. The robot identifies a small crack in a gear, a potential precursor to catastrophic failure. This early detection, thanks to the robot’s advanced capabilities, allows for proactive maintenance, preventing costly repairs or complete component replacements. The robot’s ability to access hard-to-reach areas inside the gearbox is crucial in such scenarios.

Outcome Summary

In conclusion, the 60 million dollar investment in robotics for wind turbine repairs marks a pivotal moment in the renewable energy sector. This innovative approach to maintenance holds the key to improving efficiency, reducing costs, and enhancing safety in a crucial area of renewable energy production. The future of wind energy may well depend on the success of these robotic solutions, and this investment signifies a strong vote of confidence in their potential.